Press Brake Tools in UAE Dubai

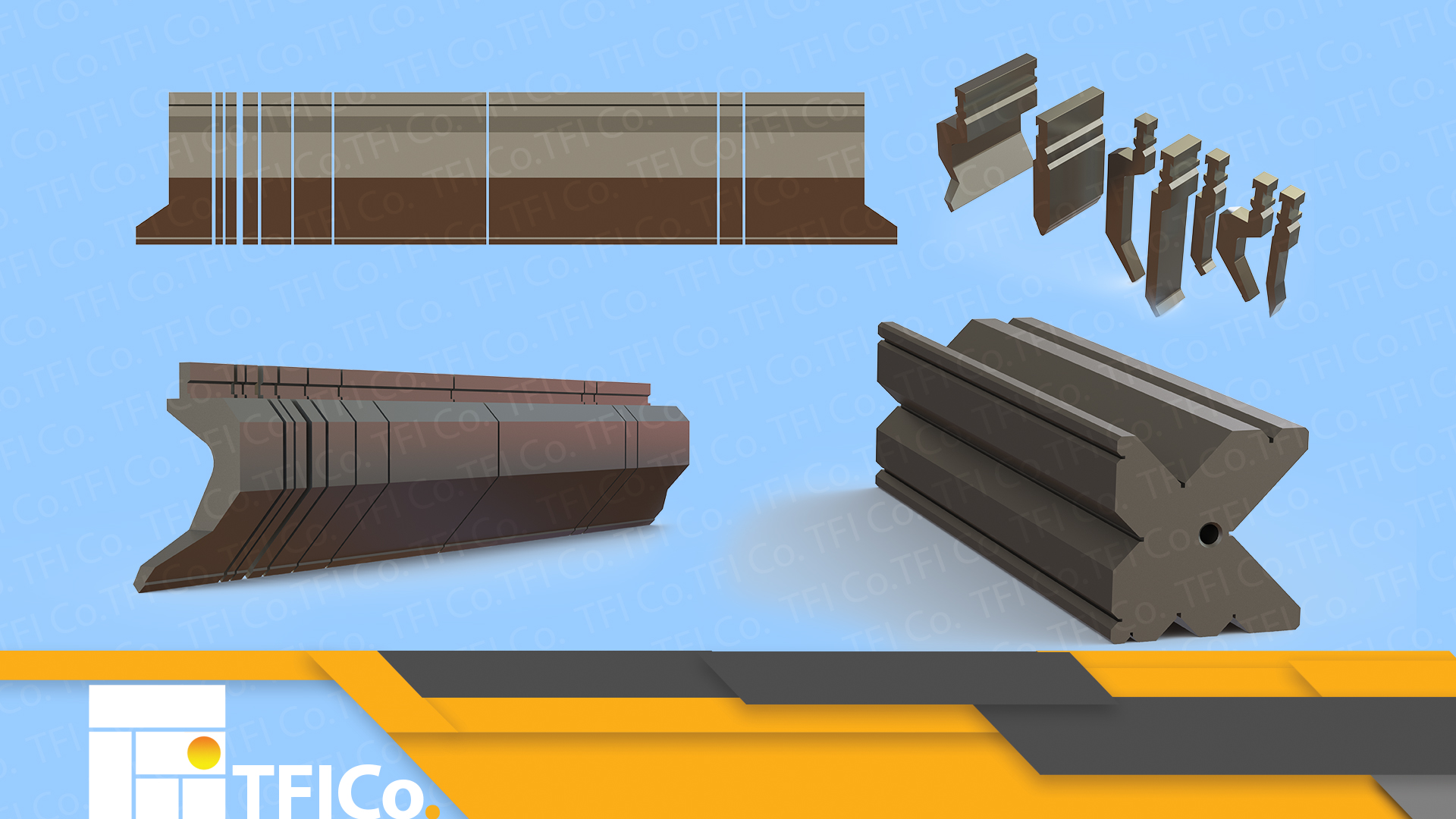

Press Brake Tools made of pure alloy steel well hardened precisely manufactured by TFICO

We share our knowledge in manufacturing of press brake tools for steel fabricators and metal working factories in

- United Arab Emirates

- Saudi Arabia

- Oman

- Qatar

- Kuwait

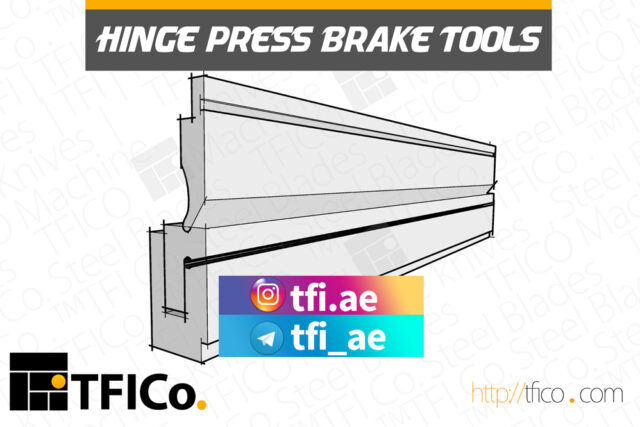

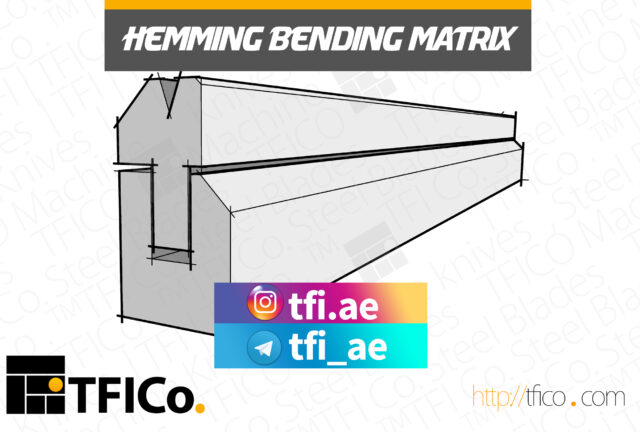

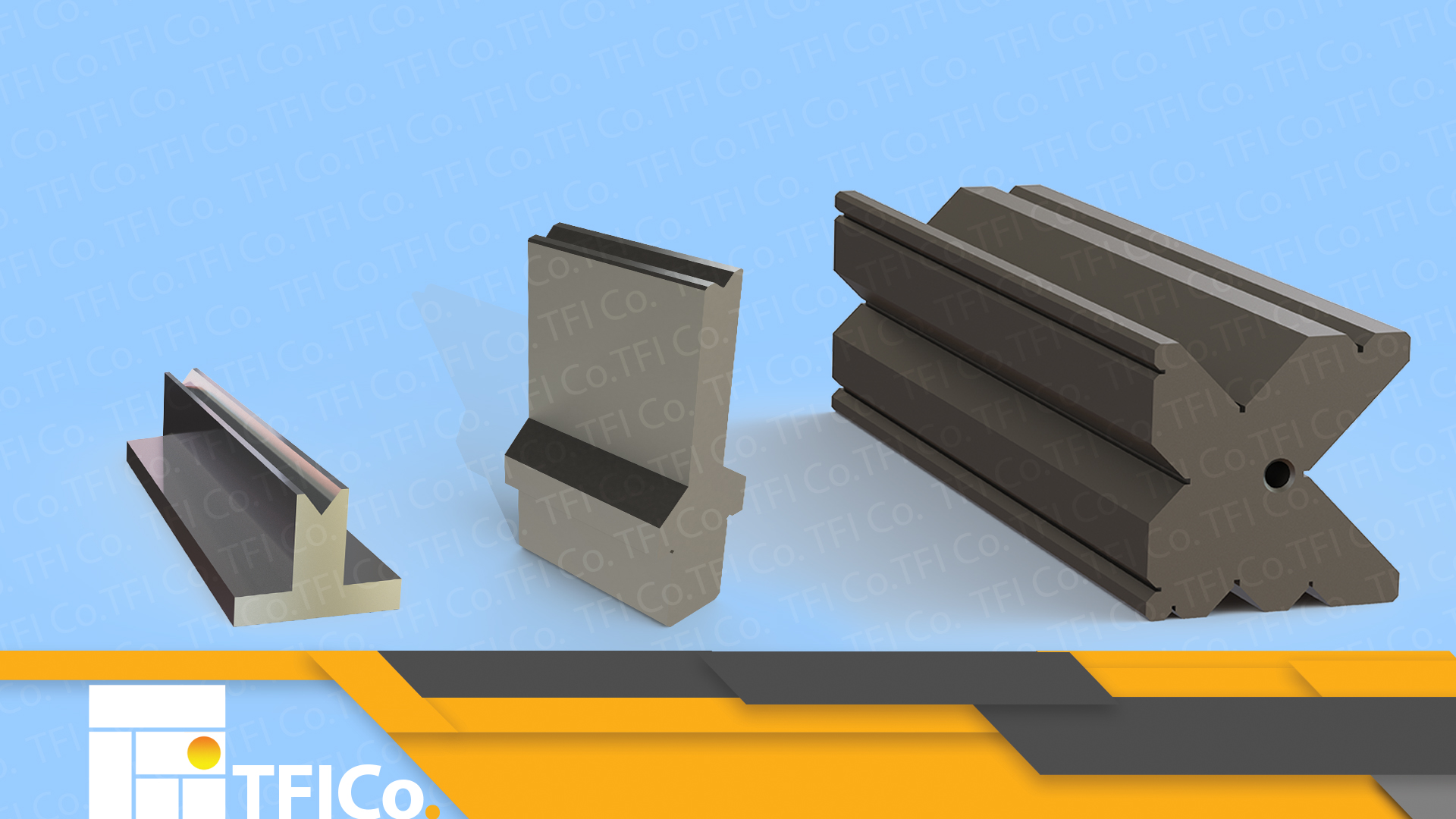

Different Types for Hemming Tools

Hemming tools prove indispensable for bending machines in air conditioning fabrication facilities, enhancing efficiency and precision in the manufacturing process.

Hemming Tools for UAE (Dubai)

Specialized Hemming Tools for Press Brake Machines

Our Hemming tools for press brake machines in the metalworking industry are specialized tools that are used to create a hemmed edge on sheet metal. Press brake machines are widely used in the metalworking industry for bending sheet metal into various shapes and forms. Hemming tools are used to create a folded edge on sheet metal, which can be used to strengthen the material and improve its resistance to wear and tear.The Anatomy of TFI Co. Hemming Tools

TFI Co. Hemming tools typically consist of a punch and die set that work together to create the folded edge. The punch is a cylindrical tool that is pressed against the sheet metal, while the die is a matching tool that is used to form the folded edge. The punch and die are typically made of high-strength steel and are designed to withstand the high forces generated during the hemming process.Versatile Applications of TFI Co. Hemming Tools

TFI Co. Hemming tools are used in a variety of applications, such as creating hemmed edges on metal parts for the automotive and aerospace industries, creating folded edges on sheet metal for architectural and construction purposes, and strengthening metal parts for industrial use. They can be adjusted for different metal thicknesses and different hemming angles.Compatibility with Press Brake Machines in UAE

Our press brake tools for UAE can be used with a variety of press brake machines around Dubai, Abu Dhabi, Sharjah, and other Emirates, including mechanical, hydraulic, and electric press brake machines. They can also be customized to meet specific requirements, such as creating hemmed edges on thicker or more complex parts.Conclusion: Enhancing Metalworking with Hemming Tools

In conclusion, Hemming tools are specialized tools for press brake machines in the metalworking industry that are used to create a folded edge on sheet metal. They typically consist of a punch and die set and are used in a variety of applications to strengthen metal parts and improve their resistance to wear and tear. They can be adjusted for different metal thicknesses and different hemming angles and can be customized to meet specific requirements.- Abu Dhabi

- Dubai

- Sharjah

- Ras Al Khaimah

- Riyadh

- Doha

- Muscat

- Kuwait

Please feel free to contact us in case of any enquiry using chat below or contact page

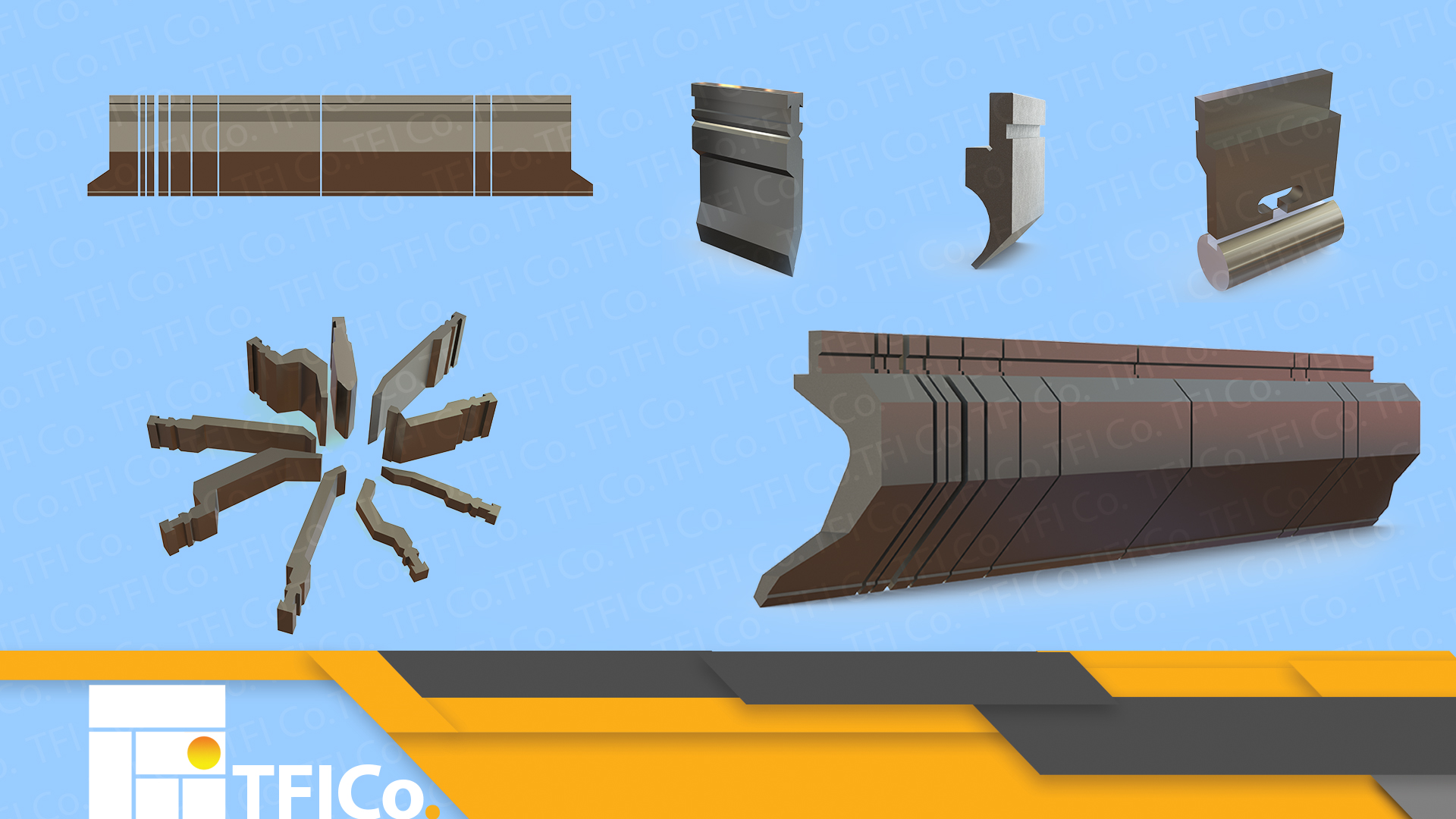

Bending Die (Matrix)

Dies are critical components in press brake bending systems, serving as the lower tools that shape metal sheets into the desired form. They work in conjunction with punches (upper tools) to create bends, angles, and contours in the metal. The choice of die is crucial for achieving precise and accurate results in the bending process.

Sub-categories of Dies:

V-Dies:

Description: V-dies have a V-shaped groove that determines the bend angle in the metal. They are versatile and widely used for various applications.

Applications: Suitable for general-purpose bending where a consistent angle is required.

U-Dies:

Description: U-dies have a U-shaped groove and are used for creating larger radii or soft bends in the metal.

Applications: Ideal for applications where a smooth, rounded bend is desired, such as in the production of certain automotive components.

Special Tooling for Specific Applications:

Description: Specialized dies are designed for specific applications or industries. These may include custom shapes, radius dies, and unique configurations tailored to the requirements of certain projects.

Applications: Aerospace, automotive, and other industries with specific bending needs often require custom dies for their unique projects.

Maintenance and Die Life:

-

Regular Inspection:

Periodic inspection of dies is crucial to identify signs of wear, damage, or deformation. Replace or recondition dies as needed to maintain bending precision.

-

Die Life:

Die life depends on factors such as material type, thickness, and the frequency of use. Proper maintenance and adherence to recommended operating parameters contribute to prolonged die life.

Material and Coating Considerations:

-

Material:

Dies are typically made from high-quality tool steel, providing durability and resistance to wear. For specific applications, carbide or other specialized materials may be used to enhance tool life.

-

Coatings:

Dies may be coated with materials like nitride or chrome to improve surface hardness and reduce friction during the bending process. Coatings contribute to extended tool life and improved performance.

Die Openings and Radii:

-

Die Openings:

The width of the die opening determines the inside radius of the bend. Different openings are used for varying material thicknesses. Selection is based on the material type, thickness, and the desired radius of the bend.

-

Radii:

Dies are available in different radii to accommodate a range of bending requirements. Larger radii are suitable for softer bends, while smaller radii are used for sharper bends.

Die Holder and Clamping:

-

Die Holder:

The die holder secures the die in place within the press brake, ensuring stability during the bending process. Quick-change systems are often employed for efficient die replacement.

-

Clamping:

The clamping system holds the workpiece securely against the die, preventing movement during bending. Proper clamping is essential for achieving accurate and repeatable bends.

Bending Punches - UAE

Description of Punches:

Punches are upper tools designed to create holes or contours in the metal. They play a crucial role in the press brake bending process by exerting force on the metal, allowing for precise shaping and forming of the material.

Sub-categories of Punches:

Single V Punches:

Description: Single V punches have a single V-shaped point that comes into contact with the metal during the bending process. They are versatile and commonly used for a variety of bending applications.

Applications: Suitable for general-purpose bending where a consistent V-shaped contour is required.

Gooseneck Punches:

Description: Gooseneck punches have a distinctive curved or gooseneck shape, allowing them to reach deeper into the workpiece. This design is particularly useful when bending complex or deep forms.

Applications: Ideal for applications where a punch with extended reach is necessary, such as in the production of certain automotive or aerospace components.

Tandem Punches:

Description: Tandem punches consist of multiple punch points arranged in tandem on the same tool. This configuration enables the simultaneous bending of multiple locations on the workpiece.

Applications: Well-suited for high-efficiency production where multiple bends need to be made in a single operation, reducing the need for tool changes.

Punch Profiles and Applications:

-

V-shaped Punch:

Creates V-shaped contours in the metal, suitable for a wide range of applications requiring consistent V-bends.

-

Gooseneck Punch:

Used for reaching deeper into the workpiece, making them ideal for applications requiring extended punch reach.

-

Tandem Punch:

Enables simultaneous bending at multiple locations, improving production efficiency in certain applications.

Material and Coating Considerations:

-

Material:

Punches are typically made from high-Quality tool steel, or other durable materials that can withstand the forces exerted during the bending process.

-

Coatings:

Coatings such as nitride or chrome may be applied to punches to enhance their surface hardness, reduce friction, and increase resistance to wear, contributing to prolonged tool life. depending on the specialist opinion.

Tool Installation and Maintenance:

-

Installation:

Follow manufacturer guidelines for installing punches securely in the press brake. Ensure proper alignment for accurate bending results.

-

Maintenance:

Regularly inspect punches for signs of wear, damage, or deformation. Replace or recondition punches as needed to maintain bending precision.