Shear Blades Guillotine Knives

TFI Co. Manufacturer of steel blades and machine knives since 1965 Produces more than 300Tons of steel blades products for middle east region per year.

Shear Blades and Guillotine knives are the major steel blades for metal working industry we manufacture.

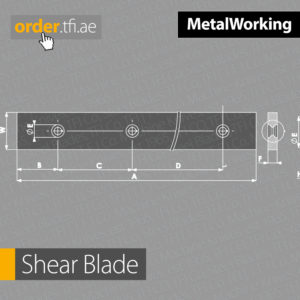

What information is needed to have price for Shear Blades?

We need Length x Width x Thickness of the Knives and the material to be cut with shear blades.

Please feel free to contact us or chat with us right here in this page to enquire about the price of your next shear blades.

Get A Quote now for your Shearing Blades

Top Shear Blade

Shear Blades with two cutting edges for purpose of being upper blade and move in swing direction to make the cutting with aid of keeping the sheets straight after the cut

Bottom Shear Blade

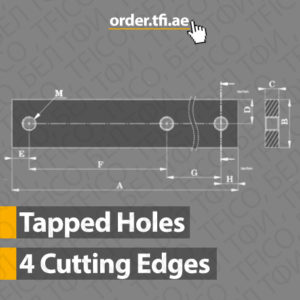

Bottom Shear Knives with Tapped Holes with M10, M12, M14 and M18 holes and distanced in regular and irregular distances for Cutting Metal sheet Made BY TFICo

Tapped Holes will have the nature of being connected to machine beds through The Allen Shape bolts or Hexagon Bolts

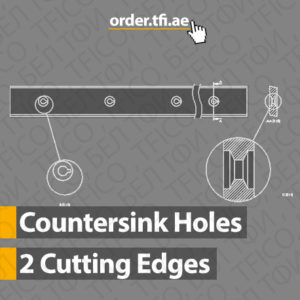

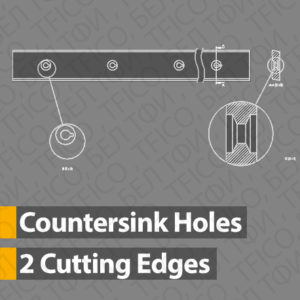

Metal Working Shearing Knives

Four Edge Shearing Knives for Metal Working Guillotine Machines in Steel Fabrication Factories and Iron Working Sites. We do manufacture the Precise and accurate Edge Shearing Blades Since 1965 and Are expert in installation of the Knives on the machine. We know the art of minding the Gap between the Knives to make the cuts with no burr

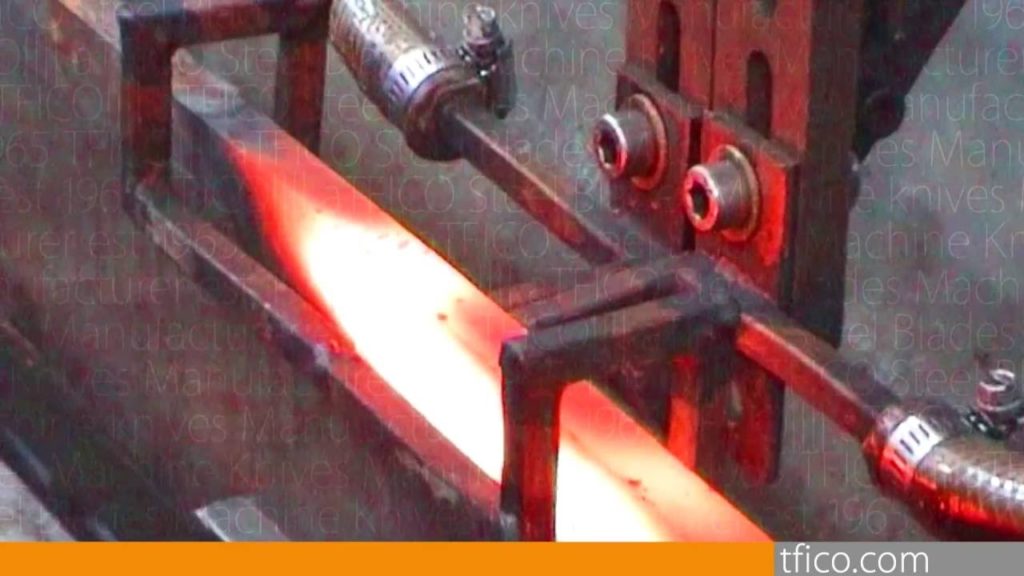

Heat Treatment

The secret to the Durability of Alloy Steel Knives are the Heat treatment the Annealing tempering and Quenching methods.

TFI’s well trained hands are educated to have the steel blades nicely treated in the fire in the Ovens. Ovens made of perfectly distributed heat over all the elements We know how to deal with Steel and master the art of Molding steel

- Full Blades heat treatment

- Induction Heat Treatment